Well, it is cold, and time to do some upgrades on the EFI, even though we are not really finished with mapping the fuel tables. the last time I drove the car, the computer quit reading the O2 sensor. The sensor is in perfect working order, just the ECU is not reading it, making it VERY hard to map the fuel tables. I had been planning on upgrading the ECU anyway, so I thought, since this one is giving me some trouble, why not do it now? (I will repair the existing ECU, most likely a very minor problem. It will be used on a riding lawn mower of mine, but that is another story!) The new ECU will give me much closer control over the fuel maps, and will enable the IAC. It is also flex fuel compatible, so if I were to ever decide to go that route, I would only need to make the fuel system E85 compatible. With the new motor that is in developement, makes E85 a very attractive fuel. The only issue with E85 is its availablity.

Well, I figured, since I am upgrading the ECU, and I had been getting some ignition noise from my CDI HEI ignition mounted in a points style distributor, I figured it was time to upgrade the ignition too. So I decided to go with a Ford EDIS distributorless ignition system.

Here you can see the coil pack mounted on the engine. One thing really nice about the Ford system is it is mostly self contained. All you need is the pick up coil, ignition coil, and module. Then only 2 wires need to go to the ECU. The PIP (profile ignition pickup) signal from the module to the ECU, and the SAW (spark angle word) from the ECU back to the module. The module interprets the signal from the 36-1 crank trigger, and sends a signal to the ECU. The ECU receives a signal just like it is coming from a distributor. So it only "sees" 3 signals per engine revolution, where as the module "sees" 35 signals per engine revolution, interpreting the signals to determine crankshaft position then sends the 3 signals per rev to the ECU.

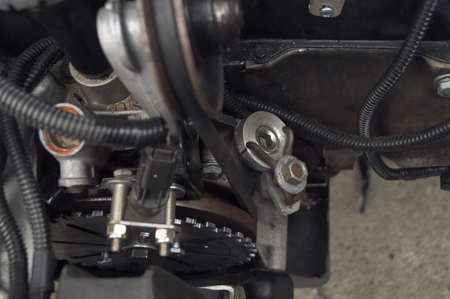

Since there is no need for a distributor, I machined down a distributor body, and shaft, to make it an oil pump drive. I did not like the idea of a distributor in the engine when all it was doing was driving the oil pump. I think this cleans up the installation some. Here you see the 36-1 crank trigger wheel mounted, along with the Escort VR sensor. You may notice that the sensor is mounted backwards from the way it is mounted on the Escort. The mounting surface is mounted AWAY from the motor, rather than toward it. This is for several reasons. First, the sensor has a 45 degree kick to it. That is because on the Escort, it is mounted flush against the front of the block, behind the belt. On my car, it is mounted well away from the block, in front of the belt. So I wanted the 45 degree kick to go back toward the motor, rather than even farther away. Next, by turning it backwards like this, it allows me to mount the 36-1 trigger wheel around 1/8" closer to the balancer than I would be able to if I were to turn it the other way around.

The Sensor is also adjustable just a little. I can close or widen the gap between the sensor and trigger wheel, and I can move the sensor a few degrees to advance or retard the timing. It is set dead on at 10 BTDC for "limp home mode" just as it should be. The ECU will change that timing as needed according to the engine RPM and manifold pressure. Now all I need is weather that is warm enough to drive in!