EFI

The car finally has all engine functions controlled by computer. Some time ago, I bought an electronic fuel injection ECU called "Megasquirt" from http://www.diyautotune.com/. You can get the ECU preassembled or in kit form. I opted for the kit form. The nice thing about ordering from Jerry at diyautotune.com is that all of the parts are clearly labeled, and carefully packaged. It makes assembly much easier.

At first, the ECU only controlled the car's ignition. I am using a GM 7 pin HEI ignition, with an MSD SS coil. There is no vacuum or centrifugal advance. All the advance curve is done by the ECU according to MAP pressure and engine RPM. With the proper code, you can make a 12x12 table, (12 RPM points and 12 MAP points), to plot the ignition advance. This is WAY better than the old mechanical distributors. I machined a 1962 Corvair distributor to accept the parts from a 1989 GM distributor. The ignition module would not fit in the distributor, so I put it in an enclosure near the distributor.

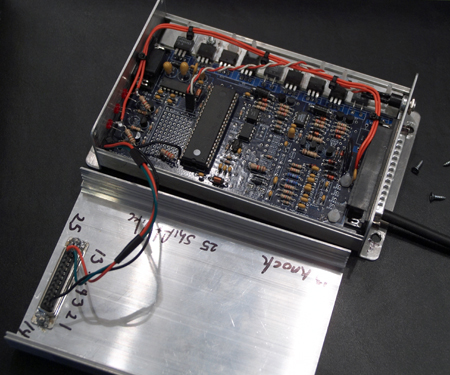

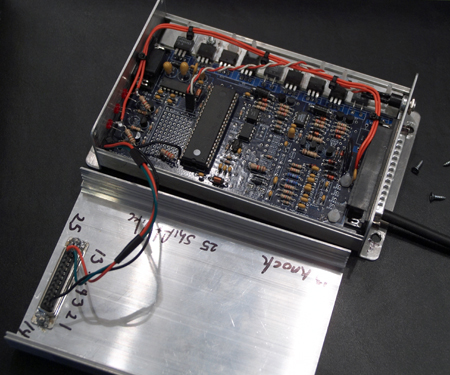

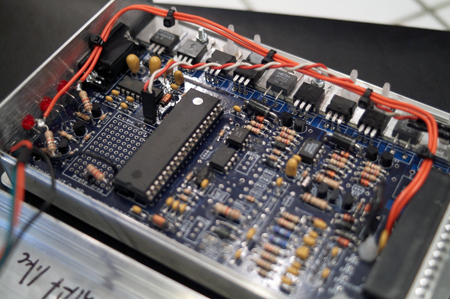

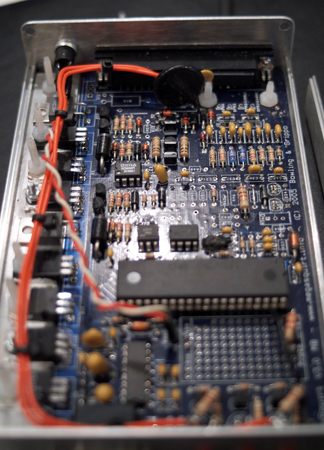

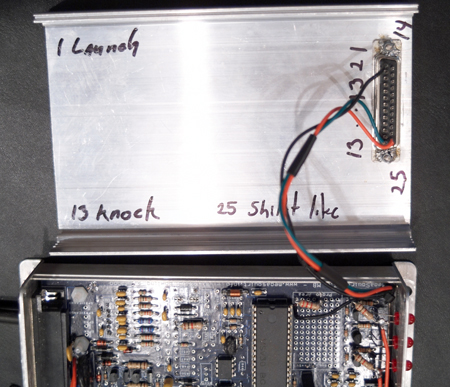

Here are some photos of the ECU. The ECU also has a launch control, (retards timing to control launch RPM to any point you set), it also controls the shift light, and has an input for a knock sensor. The ECU's uses are almost limitless. It can control EFI (wide band or narrow band O2), NO2, water injection, and much more.

The wires you see going from the circuit board to the top cover are options installed on the board. There is a lot of customizing that can be done to these units, and Jerry and Matt at diyautotune.com are about the sharpest guys I have met with this unit. They have helped me a bunch, if you are interested in putting EFI on something, or even making your regular car more "tunable" then this unit is for you. I can change anything with my laptop, (using FREE software!). You can data log, and when you do data log, it records EVERYTHING to your lap top. It records the rpm, the intake air temp, the MAP pressure, the throttle position, coolant temp, any knock condition, etc. This is one of the most useful units I have ever seen.

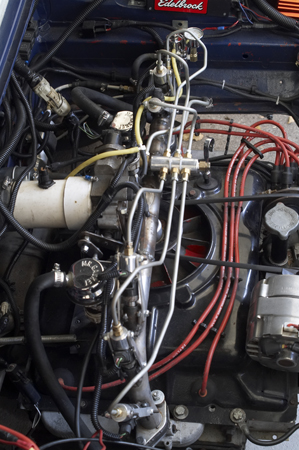

I wanted to make the EFI a "bolt on" unit for the car. I did not want to take the heads off and weld bungs on the intake. The easiest thing I could think of was to use a turbo cross over tube as an intake. The only problem with that is the opening for the inlet is well off center. So I cut the tube up, and welded it back together with the inlet centered. I also shortened the original turbo throttle linkage, and made it work with the throttle body. I increased the ratio on the throttle body just a bit over the original Corvair ratio, so the throttle opens a bit faster, but still easily controlled for the street.

As you can see, my cold air intake fits right up to the throttle body. I welded a 1/4" steel plate to the cross over tube to use as a mount for the throttle body. I then machined bungs, lowers out of steel to weld to the tube, and uppers out of aluminum. I then made hold downs out of aluminum that allow me to "aim" the injectors so they shoot as straight down the tube as possible.

I have not even set the fuel maps yet, and it runs great with what I had "guessed" at. A little tweaking, and the idle is the best it has ever been. I am running 15.3# injectors at about 80 PSI, so they flow around 19#'s. The main reason for running so much pressure is that I really want the fuel atomized well with the injectors being placed one after the other as they are. It will take a few days of driving to tune this, and I am confident that when it is done, the car will be much quicker than it was before. I am hoping that with the new gear, (3.89 and 23.2" tires), and the EFI with its larger throttle body, (1.5 square inches of inlet area with carbs, and over 3 square inches of inlet area with EFI), that the car may make it into the 15's in the quarter. I know that does not sound that fast, but we are talking about a 2800# car, with a motor that was originally 110 HP GROSS, (closer to 75 or 80 net), and in stock trim would run 20 seconds or so.

All in all, other than machining all the bungs, and cutting and welding the crossover tube, this was a pretty easy job. When I first started the car, I was having some "issues." The car idled smoothly, but only had 10" of vacuum. Then when I would accelerate, it was VERY sluggish and missed horribly. It was later when I started going over everything that I found out there was a problem with one injector bank. The car had been running on one cylinder bank! Only half the engine was working, and it still ran. I have since gotten the other bank of injectors working, and the car runs great! (Amazing how much better a 6 cylinder runs when it is running on 6 cylinders!). The weather is getting cold, not too many days left to play. I will try to do some tuning to the car in the next few days, and see if I can make a pass or two. The best the car has ever done was mid to high 16's @ around 83 MPH. I hope the car will beat that now.