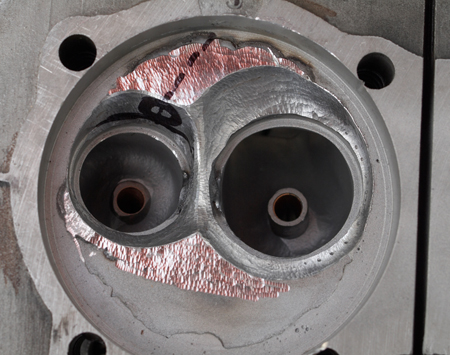

Right now I have a mostly stock 110 HP motor in the car. I raised the compression up to 10.5:1, and did some pocket porting on the heads. The motor I am building for the car, is a bit more involved. Below are some photos of a set of 140 HP heads I am building for the new motor. The heads will define the amount of horse power a motor will be capable of producing. As can be seen by the photos, there is a great deal being done to improve the heads breathing ability.

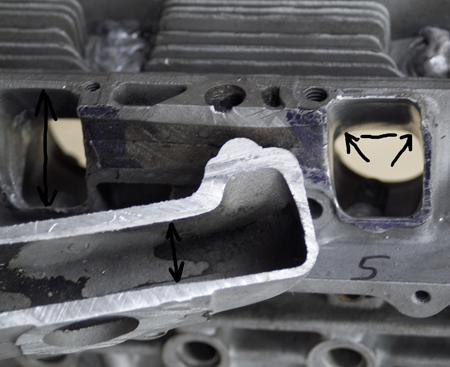

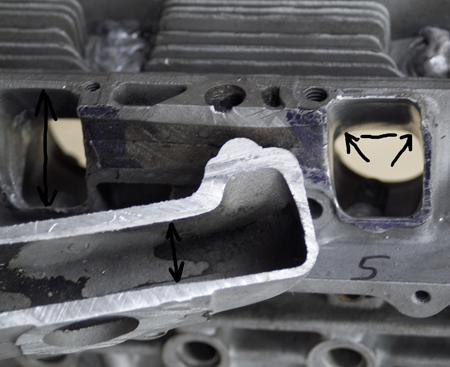

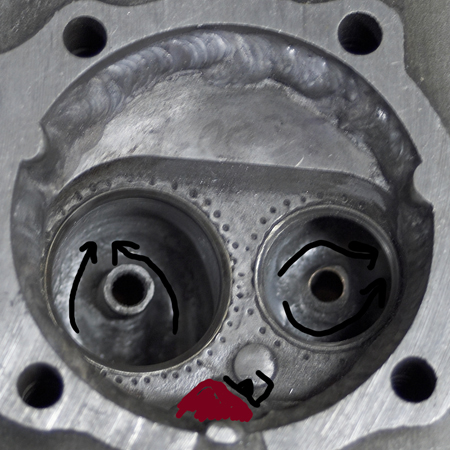

In this first photo, you can see the small cross section the stock head had in the intake manifold. No matter how much the ports are able to flow, the heads will only flow what the intake will allow. So I cut the intake off, to make the port size the restriction. The ports you see below, have not been opened up, just the surface has been cleaned up a bit. The ports are not 0.125 larger than they were stock. Notice also that the floor of the port has been widened and flattened just before the short side radius.

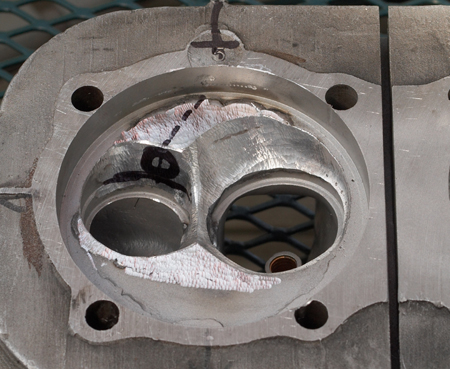

Here is a better shot of the modification to the port floor.

There is a good bit of work that can be done in the pockets also. A good flowing port is of no use if the pocket does not flow well also.

Here is another angle of the pockets showing the intake a little better

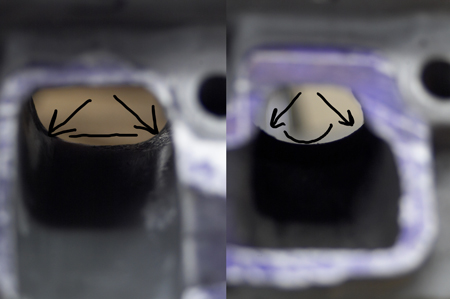

There is some power to be found by pointing the spark plug towards the exhaust valve. The Corvair head was originally a straight plug head, using a 1/2 inch reach plug. These heads are being modified to use a 3/4 reach plug angled towards the exhaust valve. This should make more power by helping ignite the fuel mixture more completely and quickly, requiring less timing lead, thereby reducing "reverse torque."

More photos will follow. This motor will be built as a "Big Bore" motor with VW 94mm jugs. As I get more parts, and have more work done I will post updates.

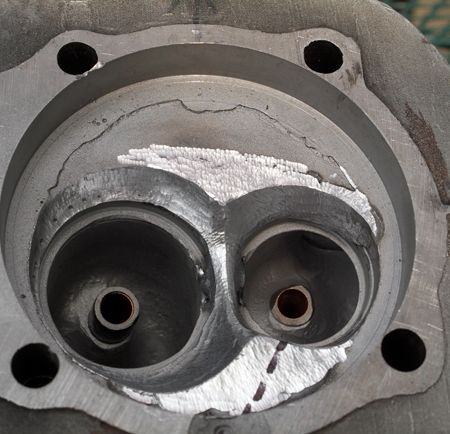

OK, here are some more photos, with more work done on the heads. The chamber is being reconfigured to be more like a late model small block head. This is still in "rough" form, and changes may still be made. In the photo below, you can see the chamber has taken shape, and the "approximate" location of the spark plug has been marked. The black marker indicates a possible angle for the plug.

Here is another view of the chamber. The heart shape by the quench area is there to help raise compression and to help the valves flow more.

Below is the old spark plug hole welded closed. The new plug will seat well down from the old one as it has to reach much farther into the chamber.

Below is a good overview of the new chamber design. It should raise compression, AND allow the valves to flow more. It will also provide more turbulence in the chamber and require less timing lead than other heads. Final valve size has not yet be determined. It is looking like possibly a 1.400 exhaust and a 1.750 or so intake. Still have more machining to do to the head, and a few more "issues" to work out. Once one chamber is done, I will simply replicate that in all the others.